A 3D Printed Car That Actually Runs

What would you think if you could walk into a car dealership, tell them exactly what you want (number of seats included) and have a 3D printed car by the end of the next day?

This may happen sooner than later.

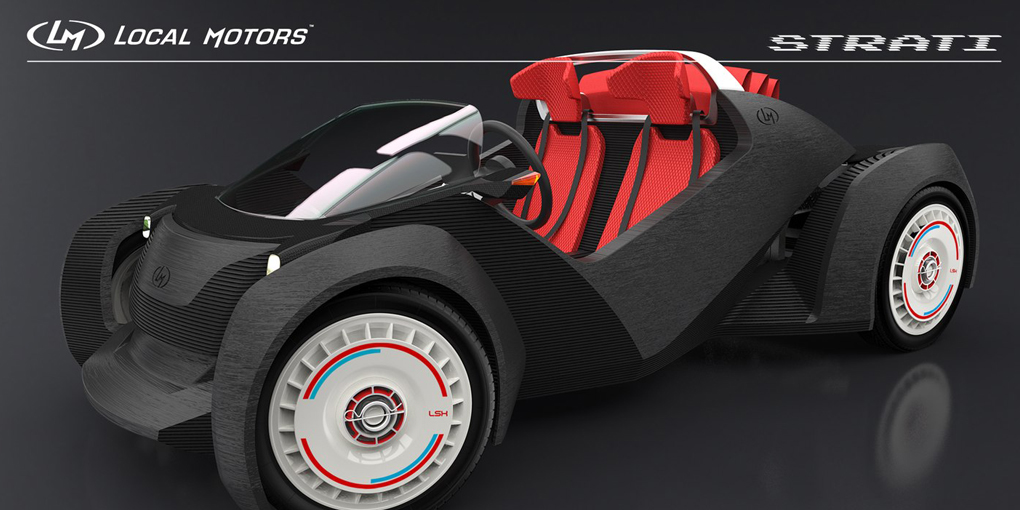

With the exception of its tires, electric motor and battery, the Strati is made entirely of 3D-printed parts. At the International Manufacturing Technology Show (IMTS) in Chicago, Local Motors (in collaboration with Cincinnati Incorporated and Oakridge National Lab) unveiled the world’s first 3D printed car. The electric, pint-sized two-seater, known as the Strati, took years to design but only 44 hours to print.

The Strati came out of a 3D Printed Car Design Challenge from Local Motors. The car has just 49 parts, including its 3D printed body (the largest part), plus more traditional components like the motor, wheels, seats and windshield. While many 3D printed car models exist, there haven’t been any drivable ones.

Printed in carbon fiber reinforced thermoplastic or ABS, the finished Strati can drive at speeds up to 40 mph and can travel 120 miles on a single charge. The car is printed in three phases – first using a Big Area Additive Manufacturing machine from Cincinnati Inc. and Oak Ridge National Laboratory. Subtractive manufacturing is then carried out using a CNC machine and, lastly, the printed portion of the vehicle is assembled.

Large format printing is something to talk about in 3D printing. Not only is it used in this case, but it is also being explored in architecture, as seen in the 3D printed castle below. In addition, it could change the construction industry forever if every applied to houses (The World’s First 3D Printed House Is Coming, And The Construction Industry Will Never Be The Same).

For more information on the Strati, check out Local Motors website here.

Top

Top